| |

CASTING

SR2 Technologieshas been offering casting services for more than forty years. Our casting and production department is equipped with the latest technologies developed for our industry.

Throughout the years, large enterprises, craftsmen and students have brought us their original models and their production moulds because they find in our casting services, the many qualities they are in need of:

- Reliability and integrity: we have adopted stringent standards when it comes to respecting the confidentiality of our customers;

- Experience and range of services offered (creation of models, casting, wax injection, size adjustment, wax repair, casting, finishing, and production). For more than forty years, we have been offering all steps of manufacturing from the sketch up to the individual or mass production;

- Flexibility and innovation: the work we have accomplished throughout the years has brought forth our diversification and the development of our competencies in various fields of activities to conquer today’s challenges.

We can also offer solutions to your casting, production and finishing problems. Casting is comprised of a series of steps, each dependent on the previous one (wax injection, casting tree assembly, plaster, firing and casting). It is crucial to have a quality control process for each step.

Our objective is to produce the best quality at the most competitive price and to offer unparallel services to all of our customers, regardless of the size of their order – may it be one piece or hundreds of pieces.

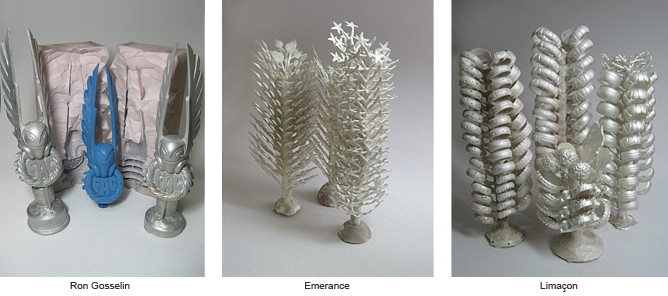

Here are some examples of accessories we have manufactured. These pictures are representations of what we can do: many of those items do not belong to us or are not in our possession as they have been designed for other companies.

For all information requests, contact us by phone at 450-654-9194 or 514-844-4586 or 1-800-844-1154, or online

List of cast metals

Platinum: (platinum-iridium, 90 Pt / 10 Ir)

Platinum is without doubt the best metal to be used in jewellery. Its physical characteristics place platinum in a class by itself.

It is dense, durable, inalterable, and hypoallergenic, on top of offering a very strong structural integrity. A platinum jewel can be worn every day while being assured that your stone settings will remain very stable. Its white color will not change, will not dull and will not be discoloured by chemical agents.

Or: (24, 22, 18, 14 and 10 carats)

Pure gold (24 carats) is a soft and very malleable metal presenting a deep yellow colour with yellow-orange tints. Coloured gold alloys can be green, yellow, rose, red as well as white. It is rarely found in tints of blue, purple and black.

All gold alloys are obtained by the addition of various amounts of mainly copper and silver, antioxidants, as well as fluidity agents such as zinc and silicon. Whitening agents such as nickel or palladium are responsible for white gold alloys.

Each alloy mix offers various mechanical and physical properties such as density, resistance, durability and ductility (malleability). The more pure gold is reduced by the addition of alloys, the more the melting temperature, the density and the malleability are reduced and the more the hardness and resistance (force) are increased.

Alloy Science Overview:

An alloy is a homogenous mix of two or more elements, at least one of which is metallic, presenting properties that differ from those of its components. An alloy is a homogenous mix of two or more elements, at least one of which is metallic, presenting properties that differ from those of its components.

The physical properties of an alloy such as its density or its conductivity may not differ greatly from those of its elements but its mechanical properties may be substantially different from those of the constituent material. This is due to the sizes of the atoms in the alloy, since larger atoms exert a compressive force on neighbouring atoms, and smaller atoms exert a tensile force on their neighbours, helping the alloy resist deformation therefore increasing its hardness and resistance (force).

Alloys can be classified by the number of their constituents (binary, ternary …) or by their properties. Here are some examples:

- Substitutional alloys such as brass (copper and zinc) where atom sizes are the same;

- Interstitial alloys that have smaller atoms filling the interstices formed by larger atoms (carbon in iron to create steel).

- Hardening alloys for very high carat gold alloys (21 carats, 22 carats and more): for example, the binary alloy (titanium and gold) is a microalloy formed by the addition of rare elements to increase the hardness and strength of 24 carat gold.

The evolution of alloys in jewellery has allowed for:

- Increased metal fluidity to obtain more precise and dense casted pieces;

- Reduced roughness (finer grain) of casted pieces;

- Reduced chemical reaction of the plaster with pieces;

- Obtaining of a metal surface with a finer and brighter crystallization.

Silver: (Pure silver: 0.999, sterling silver: Ag-Cu, deoxidized silver: 0.925)

Pure silver is one of the oldest metals known to man and was once used as currency. It is very malleable and conductive as well as inalterable. Its color is a very pure white.

Used in jewellery, it can be casted as well depending on the model and its complexities. However, those pieces present a relatively low hardness. Silver is also found in electronics due to its conductivity as well as medicine and the food industry for its antibacterial characteristics.

Sterling silver (0.925) is produced by mixing silver and copper to increase its rupture or break resistance. Its mechanical properties are much appreciated. However, it is the type of silver that oxidizes the fastest. When it is heated, a “casting skin” (copper oxide) appears on its surface, engendering polishing issues. Although it is used in jewellery, it is better recommended for plating application or thin, delicate pieces.

The development of new technologies and the latest research in metallurgy have brought forth the appearance of alloys composed of at least three elements with low fusing point such as germanium and indium partially replacing copper. They are known as deoxidized sterling silver, argentium and others. They are all resistant to oxidation and do not present a casting skin. Therefore, they have lower porosity and brighter shininess. However, their mechanical properties are lessened and they must undergo a heat or annealing treatment to increase their hardness or ductility.

Bronze: (yellow bronze: silicon, antique bronze, white bronze) Bronze: (yellow bronze: silicon, antique bronze, white bronze)

it is said that bronze originated in Mesopotamia from the metalwork of copper and tin. It was first used to produce basic and utilitarian objects such as hatchets, arms and coins. Its main strength being its hot-workability and therefore its castability, it allowed over time, for the creation of small to very large pieces.

This major technological breakthrough was at first the result of adding 10% of tin to copper to create bronze. Since then, its metallic composition has undergone major modifications and it remains to this day, the preferred metal of artists and sculptors when they create their pieces.

For every work of art, our foundry can produce your pieces under three nomenclatures:

- Original (maximum number of 12 copies)

- Multiple (numbered from the original, as per the number of multiples determined by the artist. For example: 1/100, 1/300)

- Unique piece (casted in single copy marked UP or 1/1)

All bronze artworks must be engraved visibly within their thickness, with the following markings:

- Signature of the sculptor

- Copy number

- Foundry mark or signature

- Casting year

Aluminium: (primary aluminum alloys)

Aluminum is a silver metal known for its malleability and its very low density. When exposed to air, a thin oxidation layer (alumina) of a few nanometres thick appears on its surface and prevents the progression of corrosion in normal exposure conditions.

Aluminum is used in many industries such as aerospace, transportation, packaging and construction.

It is occasionally used to create artistic work or jewels.

The casting alloys are designated by a letter and a classification composed of three digits and one decimal. The first digit represents the main alloy element. The second and third digits identify the specific alloy and the decimal indicates if it is a moulded piece or an ingot. Series 200, 300, 400 and 700 casting alloys are susceptible to hardening by heat treatment.

Conversion Tables

|

|

| Weight conversion (g) |

Multiplication factor |

| |

|

Sterling to Pewter

Sterling to 10 carats

Sterling to 14 carats

Sterling to 18 carats

Sterling to Platinum

10 carats to sterling

10 carats to palladium

10 carats to 14 carats

10 carats to 18 carats

10 carats to platine

14 carats to sterling

14 carats to 10 carats

14 carats to palladium

14 kcarats to 18 carats

14 carats to platinum

18 carats to platinum

18 carats to 14 carats

18 carats to 10 carats

18 carats to palladium

|

(g) Weight X 0,70

(g) Weight X 1,14

(g) Weight X 1,30

(g) Weight X 1,48

(g) Weight X 2,06

(g) Weight X 0,88

(g) Weight X 1,04

(g) Weight X 1,14

(g) Weight X 1,30

(g) Weight X 1,86

(g) Weight X 0,77

(g) Weight X 0,88

(g) Weight X 0,92

(g) Weight X 1,14

(g) Weight X 1,64

(g) Weight X 1,38

(g) Weight X 0,88

(g) Weight X 0,77

(g) Weight X 0,77 |

|

|

|

|

|

|

|

|

| Metal |

Wax

weight (g) |

Metal

weight (g) |

| |

|

|

Aluminium

Bronze (brass)

Sterling (0,925)

Pure silver (0,999)

10 carats

14 carats

18k carats

18 carats (palladium)

19 carats

22 carats

24 carats

Platinum |

1

1

1

1

1

1

1

1

1

1

1

1

|

3,00

8,50

10,0

11,0

11,0

13,0

15,0

15,8

16,0

17,6

19,2

22,0 |

|

|

|

|

|

|

|

Choose a service

|

|